Flow Analyzers

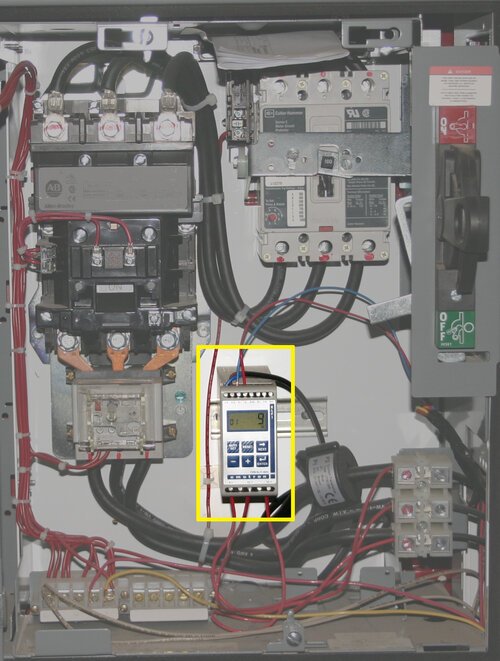

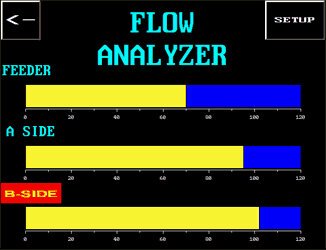

Have you ever really wanted to see the cotton split between your inclines? Flow Analyzers use precise current transformers to monitor horsepower changes as cotton flows through your module feeder and inclined cleaners. When feeding cotton into the gin, the operator basically has no feedback until the second stage inclines or the gin feeders...when it's already too late. It's a lot like driving a car at night with no lights. You can't see what's coming until you've already hit it. Whether in wet cotton or a typical variable module, Flow Analyzers allow you to see cotton flowing through machinery in real time. You can speed up or slow down based on immediate feedback allowing faster ginning in normal conditions and faster response when there's an unexpected change in cotton conditions. All Moisture Mirror models graph Flow Analyzer values over 24 hours and have an alarm to visually warn the ginner of impending problems. Mirrors can also be wired to automatically pause cotton flow when a choke is about to occur. Using Flow Analyzers gives you the ability to maximize your gin's production by running full speed, but minimize downtime because you can actually see the chokes coming and avoid them!